Applied Chemical Engineering in Petrochemical industries

This seminar presents the scientific principles and applications in the heavy chemical industry such as refineries, plastics production, and petrochemicals by examining all procedures involved.

Sub operations are described and analyzed with means of both underlying science and applied methodologies. Devices, materials and procedures are covered in depth and the use of process simulation tools aids the attendants in fully comprehending principles and applications. This seminar can be delivered in two versions: Version 1 is the standard version [20 CPD hours] whereas Version 2 requires 40 CPD hours. Contents in BLUE belong to Version 2. Other Versions can be agreed upon demand.

Objectives:

By the end of the course, participants should have:

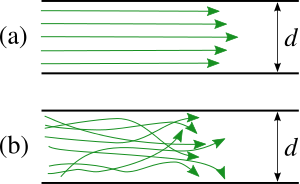

ü Knowledge on fluids and fluid flows [single and multi-component] attributes

ü Knowledge of advanced thermodynamics

ü Knowledge of using Process Simulators for design, retrofit and optimization purposes

ü Knowledge of devices and their operation conditions in these industries

ü Knowledge of advances and future research in the field

ü Evidenced various cases studies

Contents:

ü Fluid flows [single and multicomponent]

ü SimScale or COMSOL or other simulator case studies on fluid flows

ü Thermodynamic properties of flowing systems

ü Simulation of thermodynamic properties

ü Single, two and three phases diagrams

ü Pressure drops, valves and pumps

ü SimScale or COMSOL or other simulator case studies on fluid flows on Pressure drops, valves and pumps

ü Ideal and real fluids

ü Fluctuations from predicted behaviors [steady states] and measuring equipment

ü Mass and heat [energy] transfer

ü Modes of energy transfer [radiation, conduction, convection] and their characteristics

ü SimScale or COMSOL or other simulator case studies on fluid flows on Modes of energy transfer

ü Heat exchangers: design, retrofit, types, attributes, advances and new technologies

ü Simulation on HE design

ü Heat generation [boilers, radiators, furnaces]

ü Efficiency calculations; Energy and Exergy

ü Distillation [design, control, operational characteristics]

ü Purification

ü Separation

ü Simulations on Separation [HyperChem]

ü Adsorption and Absorption

ü Simulations on Adsorption [HyperChem]

ü Screening Procedures via Computational Chemistry approaches

ü Case study of screening procedures [Ionic Liquids as solvents/ absorbents for a variety of adsorbates]

ü Reactors [types, operational modes, case studies, controls, HE]

ü Reaction kinetics and Reaction routes

ü MATLAB codes for case studies in Reaction kinetics for CSTR, Fluidized bed and PFR

ü Reaction rate equation and optimization

ü Reaction rate diagrams and conditions prediction

ü Hydrocarbon mixtures

ü Modeling of Hydrocarbon mixtures at micro scale [HyperChem]

ü Industrial solvents and novel advances [Ionic Liquids]

ü Case study: Simulation of organic industrial solvents and Ionic Liquids based solvents

ü Compound identification [Spectrometry and Sampling]

ü Process Simulator Introduction and case studies [Determined among a number of choices. Version 2 covers 5 case studies, Version 1 covers 2 case studies]

ü Physical and Chemical processes Simulator Introduction and case studies [HyperChem, HyperCube Inc. or other for both versions]

Who should attend?

ü Chemists, Chemical Engineers, Industrial Engineers

ü Laboratory personnel/ researchers

ü Scientists from other fields that require a detailed overview/ introduction to the topic

ü Operations supervisors/ managers