Zero CO2 emission power plant design & optimization

Power plants produce energy by using the chemical energy of fuels via a variation of thermodynamic cycles. Older power plants were based on combustion of fossil fuels (mostly coal) and produced electricity with an efficiency of up to 33-36%. Combined generation of electricity and thermal energy (heat) further increased this efficiency up to 46-49%. Newer plants based on cleaner fuels, such as natural gas, exhibit efficiencies up to 55% when in cogeneration mode. However, the most important issue of our times is the reduction of Carbon Dioxide emissions, a problem stated as Carbon Capture and sequestration, CCS.

Carbon Dioxide capture can be pre- combustion or post- combustion. The two different approaches have a different financial and technological impact on the plant’s operation and efficiency. In short, pre- combustion capture major features include:

- Higher efficiency in new plants

- Higher Carbon Dioxide removal capacity

- Lower cost effect in new plants

- Heavy cost and efficiency penalty when retrofitting old plants

- Usually applied via gasification of the initial fuels, thus ‘removal’ of the carbon content before the combustor

Post combustion on the other hand, exhibits the following attributes:

- Based on adsorption, absorption, membrane separation, and condensation

- Easier to use in existing plants

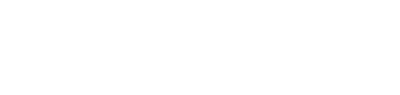

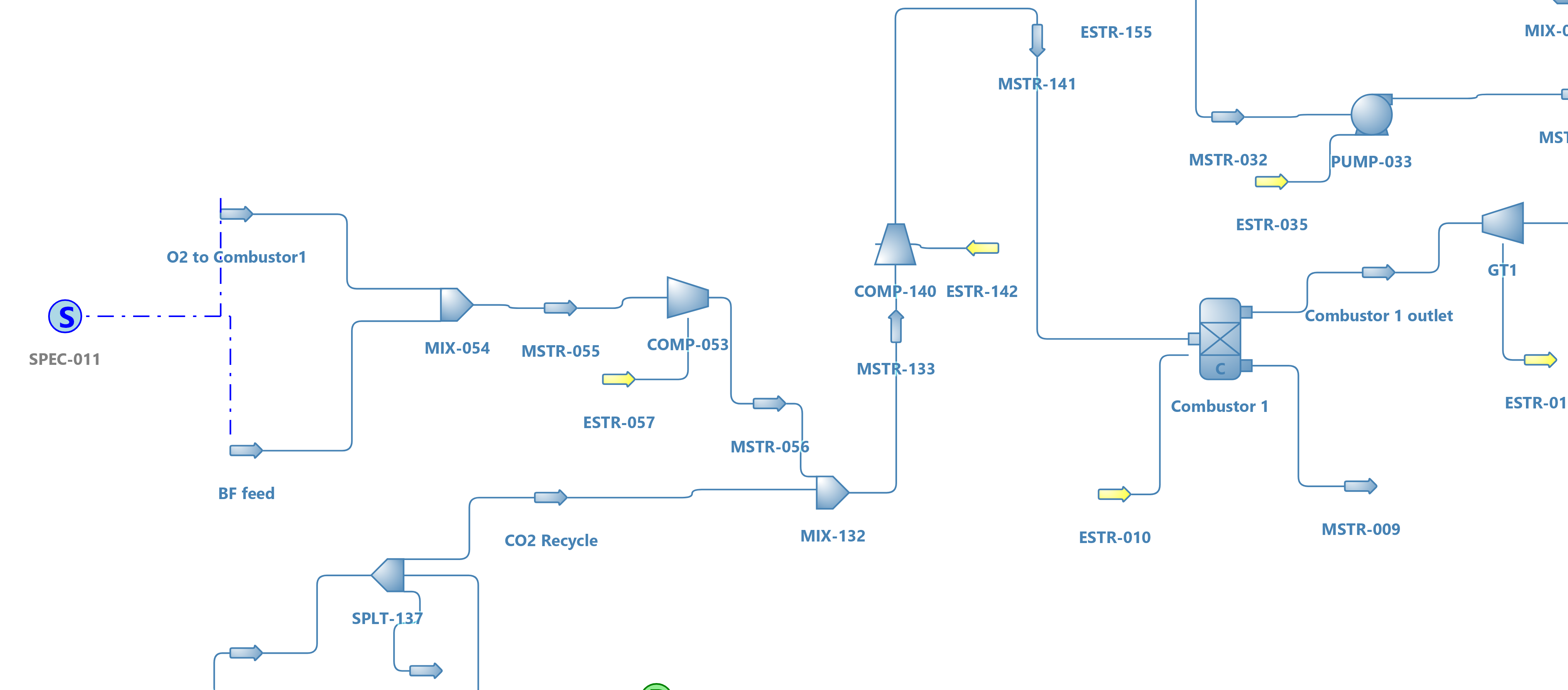

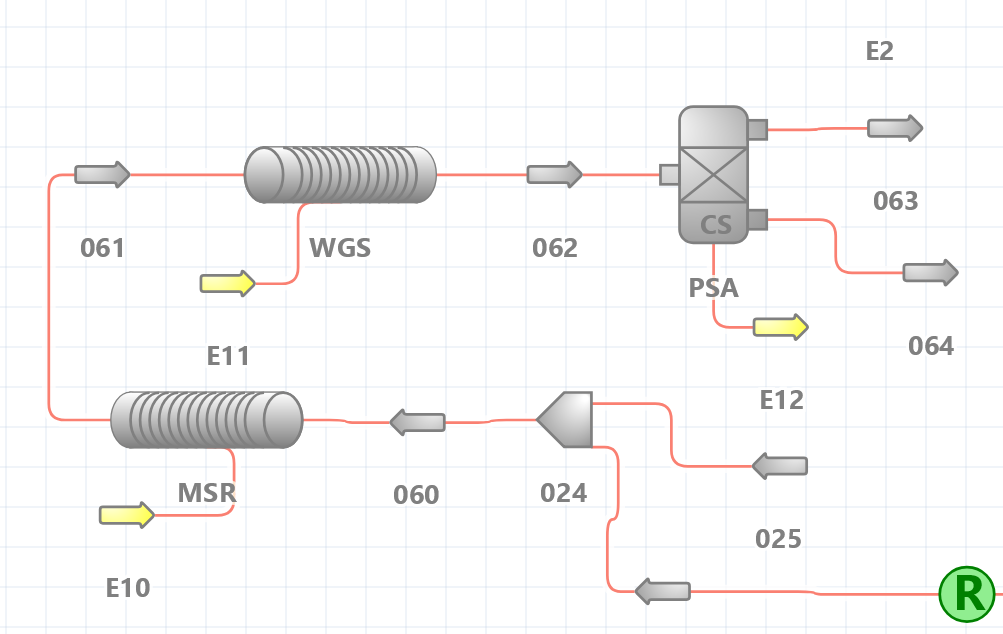

Carbon Dioxide capture almost always induces a cost on the overall energy generation process. Any Carbon Dioxide removal approach uses sub processes that raise the overall cost of generating electricity. In our ongoing work with INDUSTRIASYS (industriasys.com) we co- invented a novel, zero emissions power plant with 100% Carbon Dioxide capture, at low cost that is covered internally by other gains we achieved. This plant uses a combination of existing and new technologies that include but are not limited to:

- Oxy fuel combustion that only produces Carbon Dioxide and Water as products, and thus eliminating NOx and SOx emissions

- Oxygen generation from atmospheric air via a cryogenic distillation and / or pressure swing adsorption

- Oxygen generation via an electrolytic module

- Hydrogen generation via an electrolytic module

- Easy separation of Carbon Dioxide from Carbon Dioxide rich flows

Our work included (still ongoing):

- Creating of the Process Flow Diagrams of the plant wide processes

- Optimization of the different variations of the Process Flow Diagrams

- Device / Process sizing and specifications

- Patent description and write up

- Novel technologies investigations

- Combination of break throughs in different scientific fields

Process simulation work was carried out in DWSIM and ASPEN. The work continues as new components and variations are added continuously.