Precision Liquid Application

Precision Liquid application is required in a variety of applications, and these applications continue to grow in number. Precision liquid application offers unique advantages to the use / developer, and some of them can be listed as below:

- Savings on liquids used

- Precision on target

- Time savings

Application fields include but are not limited to:

- Automotive painting

- Metallic painting in general

- Painting in general

- Disinfection of large or difficult areas to reach via traditional methods

- Agriculture, both for nutrients and pesticides delivery

- Water delivery

- Coating preparations

- Others

Two approaches stand out when such a controlled delivery is required by spraying: traditional spraying/ atomization and electrostatic spraying. Each presents advantages and limitations, and the optimum choice depends on the system under investigation, fluid properties, energy consumption constraints, delivery mode, distance to target, and others. Electrospraying is commonly the most suitable choice when:

- Parts of the surface area to be sprayed are difficult to reach, as for example the surface below a bus seat

- Parts of the surface area to be sprayed can be considered significantly charged in either way; sometimes the electrosprayer can work in a reverse- changing fashion, by firstly charging an area and then using a reverse charged spray to cover this area with high efficiency

- An exact droplet size distribution is required; in this case, the energy provided by the electric field is used to create a homogeneous dispersion in the flow

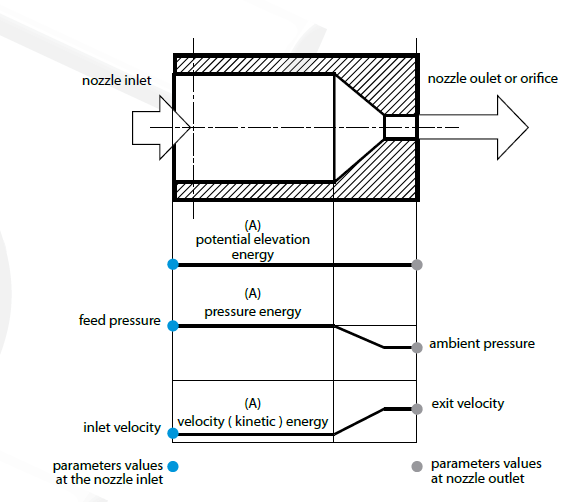

When the traditional spraying / fogging is applied, the following must be considered:

- Particle/ agglomerate distribution mainly depends on the nozzle type, thus a ‘perfect’ nozzle must be identified for each application [if it exists]

- The costs are much lower

- Particle size distributions are ‘moved’ to larger sizes

- Inaccessible areas remain unsprayed

The main issue among those mentioned, the agglomerate particle distribution can be addressed by more ‘creative’ approaches, especially in the pre-mixing of the flow and the nozzle design. Our client has asked us exactly this, and we came up with a solution for the optimization of spray delivery with a maximum accuracy, from a distance up to 20 cm.