Friction Losses comparison between two different material choices

Our client was active in the PE lined composites, and asked us to investigate whether it would be feasible for specific industries and ships to change their existing metallic fluid flow media [pipes, junctions, fittings] with PE coated ones. The study should investigate the potential benefits in terms of pressure drops, friction losses and overall feasibility of the hypothesized substitution.

Our team undertook the investigation working in three parallel pathways:

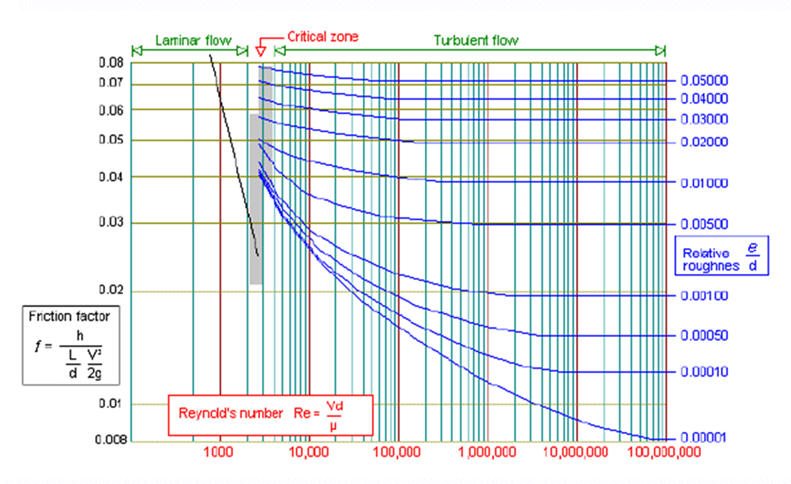

1- The first sub study investigated the friction losses and pressure drops by working on the actual mass, energy and momentum balances and the losses due to the roughness of surfaces in contact with the flow. It involved calculation of Reynolds numbers, characterization of flow regime, calculation of friction factors from the Moody diagram, and trial and error cycles.

2- The second pathway involved the use of process simulation to calculate the pressure drops and related energy requirements for each scenario [metallic vs PE coated metallic] in DWSIM and ASPEN. A variation of setups was employed for both simulators.

3- The third pathway involved the use of Computational Fluid Dynamics, and the adaptation of the required flow and solid modules in SimScale. The CAD drawings of the said system were already available from the client’s side. CFD simulations resulted to additional flow properties profiles that enriched the findings of the previous two approaches

All three methodologies were in excellent agreement with less than 3% deviation in the energy savings predicted. The investigation resulted into a complete device- level comparison between the metallic and the polymeric coated metallic surfaces and an overall system – level comparison. It was confirmed that more than 55% of the flow energy consumed could be saved with the new system.