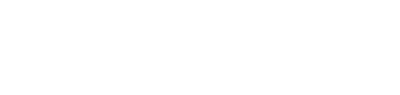

Chemical Processes design with COCO

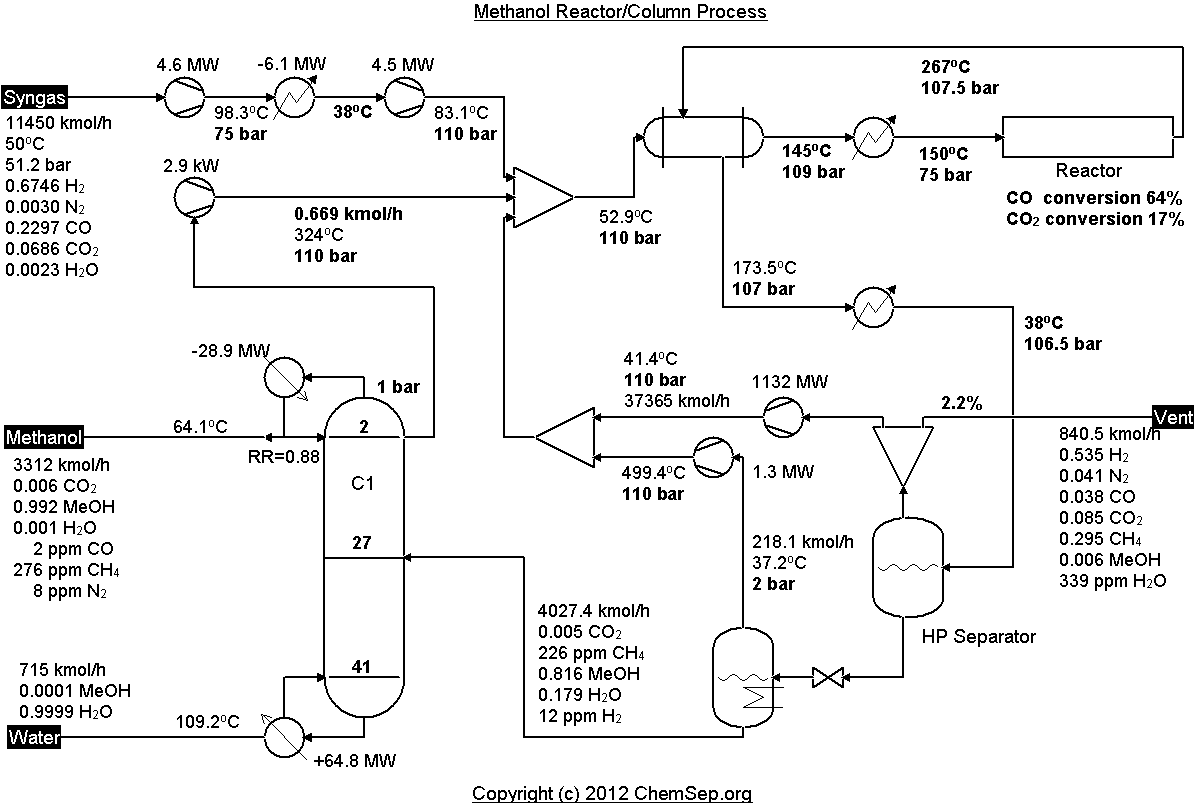

COCO is an excellent and very popular process simulator tool that is capable of simulating all the sub processes of a chemical plant, and the overall connected operations in a chemical plant. COCO includes different modules for sub operations such as:

-- distilation

-- separation

-- mixing

-- reactors

-- tanks

-- pipes

-- drums

-- adsorption

Project's target was to investigate the separation of a hydrocarbins mixture [10 components] for a pilot plant of an auxilliary operation of an existing refinery. The targets of the project can be summarized as:

> Optimization of separation devices

> Minimization of energy consumption

> Identification of optimum temperature, pressure and flow rates in the separating sub system

> Creation of the designs of the sub system

> Mass and heat balances before and after connection to the main plant [existing refinery]

> Integration of the sub system to the main plant

> Optimization confirmation for the main plant

Our work has led to efficient separation of the hydrocarbons, initially into valuable and less valuable streams and in the end into three valuable streams and the by products, with an overall energy saving that reached 15%. Connectivity to the main plant was confirmed.