Amino functional polysiloxanes synthetic pathways

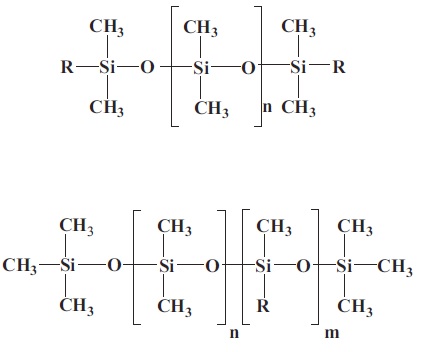

First part of this work covers reactive substituted siloxanes that are commonly used in the fabrics and textiles industry, as requested by the client. All manufacturing pathways are reviewed and explained so that the client can manufacture them from commercially available products such as PDMS. In addition to these methods, specific novel synthetic pathways are also presented as published in the scientific literature.

One very important segment of reactive amino siloxanes are the Poly dimethyl siloxanes bearing amino alkyl groups as terminal or side chain moieties that have found a broad application as polymer modifiers, fabric conditioners, release agents, and hydrophobizing agents. Poly Organo siloxanes (silicones) having an inorganic main chain, comprising alternating silicon and oxygen atoms, with organic substituents at silicon atoms are one of the most important and intensively studied classes of organometallic polymers. Application of polyorganosiloxanes and tailoring their physical, chemical, mechanical and thermal properties is a growing scientific field.

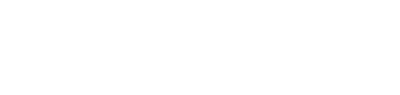

Polysiloxanes with aminoalkyl moieties are often referred to as amino silicone fluids or amino silicones. These functionalized organosilicon polymers have a wide range of applications. Due to their unique amphipilic properties, excellent spreadability and ability to form aqueous micro-emulsions, aminosiloxanes have been used in cosmetic products and textile applications for decades. The amino-functional silicones are also applied in some other areas such as treatment and modification of metal and mineral surfaces. The aminoalkyl groups can be either attached to the terminal silicon atoms of the linear polydimethylsiloxane chain or introduced as the pendant groups randomly distributed within the siloxane backbone. The properties of amino-polysiloxanes are well controlled by the structure of aminoalkyl moieties, their concentration and average molecular weight of the polymer.

Numerous synthetic approaches have been identified and presented within this report. It is obvious that the next step should be to specifically apply these methods in order to achieve specific species manufacturing. Client’s ultimate goal is to be able to self- synthesize specific chemicals; this is possible as it has been proved within this study. The chemicals of interest belong to the chemical groups investigated and analyzed.