PEBAX - Ionic Liquid membranes for acidic content removal from natural gas

PEBAX grades have been recently been utilized for the manufacturing of highly porous membranes, used for the separation of different classes of gases such as CO2, acid gases, and others. PEBAX grades offer numerous possibilities for the membrane manufacturing industry due to their specific tailorable properties such as mechanical strength, elasticity, permeability, tailored selectivity and others. Our work was to ghost write a series of scientific papers on the manufacturing and use of different PEBAX based membranes. Some of these papers have already been published, while others are pending approval.

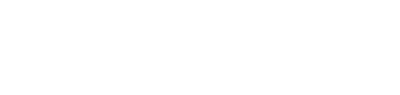

PEBAX membranes are a relatively new means in acidic content removal technology. PEBAX is a known manufacturing material for membranes of different applications, mainly due to acceptable thermal and mechanical properties of the precursor and the final product. Acidic content removal is a key issue in many industries, with most important ones being petrochemical, oil and gas and chemicals manufacturing. One especially important case is that of natural gas in which depending on the region of production, different amounts of carbon dioxide and dihydrogen sulfide can exist. These concentrations that can range from less than 1% to 20% in some cases, cause significant problems to natural gas flow in pipes, to its thermal value and its other chemical and physical properties of secondary importance.

Carbon dioxide and dihydrogen sulfide can cause corrosion within the transferring pipes that in turn can lead to often shut down for maintenance, increased costs for maintenance and repairing, leaking and other issues. Protecting these pipes with internal insulation layers against corrosion can work but is too expensive. Modifying pipes diameters and flow properties also can have an impact but the associated capital and operational costs are too high. The logical approach is to capture and remove acidic content, preferably in one stage, with as low a capturing cost as possible. Such a purification of natural gas streams is known to occur via absorption with ‘sweat’ compounds like amines, via separation in ceramic or polymeric membranes, via adsorption in porous surfaces and other less popular and effective approaches.

Absorption of acidic gases is a simple process; natural gas stream passes above an amine pool and the acidic content reacts with the amine towards formation of salts in the liquid phase. The process is simple, and operational costs include control of temperature for the amine- acidic reaction and new amine flow in the liquid phase. Adsorption works through the passing of natural gas stream through a solid adsorbent [a collection of solid particles of different sizes and porosity] that exhibits high affinity towards acidic content but not towards the rest of natural gas constituents. Costs of this process include regeneration of the solid adsorbent and pressure drop through the solid adsorbent [fluidized in many cases] region. Membrane separation is based on the existence of a porous membrane that allows some compounds to pass through its porous structure while others are totally excluded. This way and depending on the relative permeabilities of the different constituents, a very efficient separation is evident. Costs include cleaning of membrane surface if blocking occurs and higher initial capital costs. Common issues with most membranes include thermal and mechanical degradation due to the conditions of natural gas flow in the pipes.

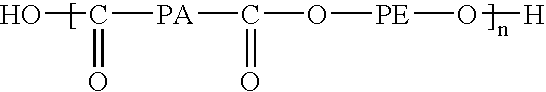

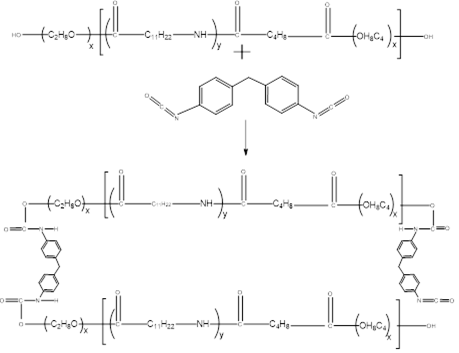

The solution we worked on utilized PEBAX – Ionic Liquid membranes that exhibited superb mechanical and thermal properties in comparison to initial pristine PEBAX membranes. It was found, through computational chemistry simulations, Computational Fluid simulations and experimental work that the actual thermal degradation temperature and loss of mechanical strength greatly varied between pristine and modified PEBAX membranes. Separation of different natural gas streams was more efficient than known separations in similar membranes.

A series of mechanical properties was investigated, and crosslinking was also studied as a part of a next project. Our work on PEBAX membranes modification via crosslinking and inclusion of Room Temperature Ionic Liquids still produces new results [2018].