MatLab Training for Chemical Engineers

MATLAB is one of the greatest tool for the scientist and the engineer in particular. Its built-in features allow for the solving of very complex systems of linear or differential systems via analytical and / or arithmetic approaches. Some of the most troublesome issues an engineer has to face include large systems of perplexed equations, that either need to be accurately solved or graphed. MATLAB is perhaps one of the top packages in the market today for that purpose.

During the last years we have delivered different versions of MATLAB training to engineers in European and Gulf based organizations. Most of the engineers were looking for a tool to:

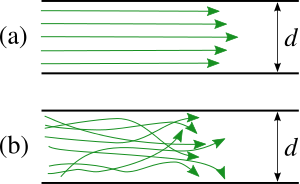

- Study reactor design, operation and control. Reactor is design is based on the mass balances and energy balances plus the mixing mode of its type. In three dimensions, one can get a very complex system of linear and differential equations that are both functions of space [x, y, z] and time. Special cases reduce the complexity of the problem [steady state, ideal reactors] but these cases most of the times are far from real life operation modes in industry. During our courses we explained all governing equations for mass, energy, momentum balance and mixing modes for a number of cases. We studied simplified cases as well. We presented MATLAB codes for various scenarios and we used these codes to compare different reactors under different operating conditions. Optimization of reactors was also studied in terms of costs, efficiencies, residence times and other factors of interest. Plotting composition profiles vs time was a major component of these courses. Plug flow, CSTR, fluidized bed reactors were investigated in detail.

- Reaction kinetics was another popular topic. Reaction kinetics depends on reaction order, catalytic or non-catalytic operation, activation steps, compositions as functions of time, adsorption, desorption and diffusion stages, temperature, pressure and other parameters. Reaction kinetics is one of the key factors in reactor design, operation and control. During our courses we developed codes for the investigation of different reactions, of different orders, under varying conditions. We also showed ways to ‘step in’ to a reaction and create ‘jumps’ or ‘stagnation’ in composition in order to change the equilibrium of a reaction. Exothermic and endothermic reactions were investigated, and other thermodynamic concepts have been used to identify direction of the reactions [Gibbs, entropy changes]

- Thermodynamics and thermodynamic properties are also common contents of MATLAB courses. Calculation of material or mixture properties is a typical MATLAB operation, as well as entropy calculations, Gibbs free energy calculations, specific volumes, etc. Phase diagrams can also be calculated and plotted based on equilibrium data or equations for every material or composite of interest. 3D phase diagrams were also exhibited as examples

- Other common topics included catalytic reactions, adsorption, absorption, extraction, distillation, etc. Each one of these topics has been investigated, having all governing equations solved numerically or analytically. Numerous cases studies for each topic are covered and studied during our courses.

Other examples of similar works using MATLAB or similar tools can be found in our BLOG section.