Process Simulation

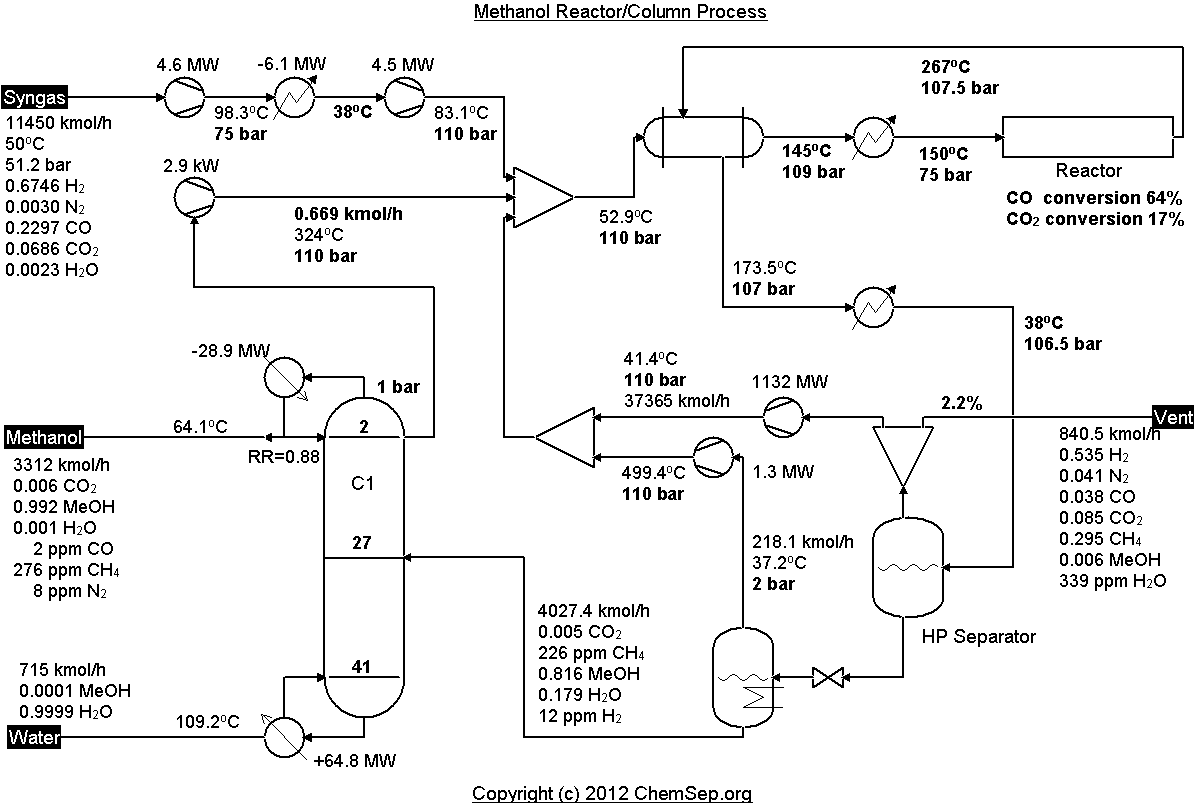

Process simulation is a field combining chemical engineering, thermodynamics, process engineering, software engineering in order to provide accurate and reliable predictions for chemical plant design, control, operation, optimization and retrofitting. Process simulation is a complex scientific approach that is used in order to allow the engineer/ user/ designer set up functional chemical plants or just sub systems of chemical plants. Each device is simulated/ modeled separately by automatic solving of mass and heat transport equations, reaction kinetics, thermodynamics, material properties equations, constitutional equations and design/ function equations of various devices. The next step is the connection of chemical devices in order to optimize the overall efficiency of the chemical process/ plant under investigation.

Process simulation is currently the only reliable approach for fast and reliable process design, operation and modification. Numerous commercial packages exist that offer specialized functions such as advanced devices set up and options, fluid flows models, reaction kinetic models, properties degradation and others. The more the concepts and equations included in these packages, the larger the computational requirements both in terms of power and time.

Commonly, by using process simulation you can design and optimize processes such as:

- Distillation [single, multiple, adsorptive, reactive, extractive, vacuum, etc]

- Separation [membrane, filters, extraction, etc]

- Reactors [Batch, CSTR, PFR, combinations, in series, in parallel, etc]

- Mixers [fluids, granules, gas, gas-liquid, gas-solid, etc]

- Boilers

- Heat exchangers

- Pipes

- Valves

- Tanks

Material selection and properties is another common feature of process simulation. Via advanced option the designer has the ability to investigate material selection effect on a single chemical device efficiency and stability or at plant wide basis. Currently, process simulation finds applications in every chemical plant, including:

- Oil and gas

- Chemicals

- Manufacturing

- Foods and beverages

- Plastics

- Energy

Our services include:

- Mass and energy balances

- Reaction modeling

- Thermodynamics investigations

- Separators modeling

- Reactors modeling

- Mixers modeling

- Adsorption modeling

- Distillation modeling

- Plant wide modeling