Hydrogen Energy outlook [May 2016]

Hydrogen energy has seen some very significant improvements during the last years, mainly due to new ideas based on older findings, such as novel storage materials with combined physical structures of different precursors. The main obstacle in hydrogen use as an efficient energy carrier has been its low volumetric energetic capacity in contrast to its high mass energetic capacity. For this reason, although its use presents unique advantages, its use has been stalled during the last years.

Up to date hydrogen could be stored and transported via one of the following approaches:

- Compression

- Liquefaction

- Adsorption in porous media

- Formation of metal hydrides

And other less successful approaches. Each of the above demonstrates pros and cons, which ultimately lead to a slowing down of mass acceptance of hydrogen as a commercial energy carrier. Compression requires extremely high pressures in order to be financially feasible and cylindrical carriers that can withstand these pressures and changes in weather conditions. Novel, graphitic fiber based composites have offered a step forward in this technology since the new composites are lighter than steel and can take pressures that are significantly higher. The manufacturing pathways for the development of fiber/ steel composites are well established procedures and compression is expected to offer higher profit margins to manufacturers of tanks / storage vehicles and hydrogen producing and consuming organizations. Compression is used both for short and long deliveries, offering a boost to all production-delivery systems across the globe. Safety hazards are minimized with the fiber/ metal composites leading to lower insurance fees for manufacturers and delivery organizations.

Liquefaction is based on the removal of energy from hydrogen gas in order to obtain larger quantities of hydrogen transported as liquid hydrogen for long distances. It is estimated that almost 30% of the energetic content of hydrogen is required for this process and this attribute makes it feasible only for use long distances application. Adiabatic tanks/ carriers with cooling installations are required in order to minimize vaporization and increase of safety risks. No significant achievements have been reported on vaporization of hydrogen thus the profit margins and transportation volumes are expected to remain at the same levels for the near future.

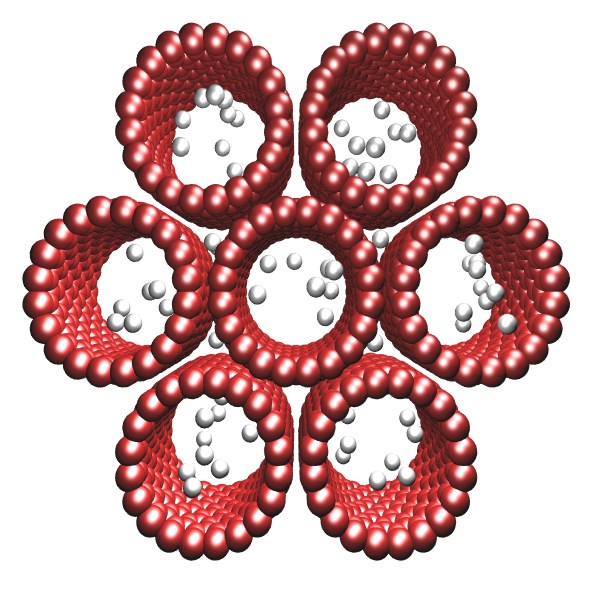

Adsorption in porous media has produced great progress during the last years. Novel materials have been predicted, synthesized, and tested for the adsorption and storage of hydrogen gas. In addition to the classical microporous carbonaceous adsorbents [graphitic nanofibers, activated carbons, etc], carbon nanotubes, metal organic frameworks, ordered silicas and zeolites, new families of adsorbents have attracted significant attention. Among them, the ones that present real opportunities are:

ü Molecularly imprinted polymers. This family of polymers allows for controlled pore size distributions [PSDs] of their porous network thus increasing adsorption and desorption efficiency, while allowing for easier prediction of modifications effects on hydrogen storage. Novel methodologies have been reported for manufacturing such micro or mesoporous ordered networks that allow for storage efficiencies that reach DOE limits.

ü Ordered microporous carbonaceous materials have been recently synthesized using microporous templates. These materials exhibited adsorption efficiencies higher than DOE requirements. Energy consumption reduction is feasible during the synthesis of these materials and investing opportunities exist in the field. Subsequent modification of these materials’ structure via insertion of metals, amines and other nitrogen containing compounds have led to superb adsorption efficiencies. Amine production and amine doping of these [and others] materials is expected to boost the market in the years to come. Amines are most commonly used for CO2 absorption from fluid streams and their potential has been recognized for the last years. The ordered microporous networks can be manufactured based on both natural and synthetic sources. These materials are expected to play a great role in the filter making technology as well, including air and water purification filters, contaminant removal from industrial wastes, and others.

ü Covalent Organic frameworks that demonstrate specific weight advantages when compared to their Metal counterparts [Metal Organic Frameworks, MOFs]. Like MOFs, COFs possess unlimited synthetic potential which has not been fully used up to date.

ü Combined mesoporous – microporous networks. This approach has led to higher diffusion and adsorption rates due to the combination of large entry pores and narrow adsorbing pores. Combinations of this kind have only been reported for specific couples of adsorbents and the potential seems unlimited. Should the approach be adopted, it is expected to provide a market boost both in manufacturing of the media and the hydrogen producers as well.

The advances in 3D scanning and 3D printing are expected to boost the above mentioned adsorbent families due to the straight forward manufacturing of the most desired physical and chemical structures at atomic level.

Formation of metal hydrides continues to be a promising methodology for hydrogen storage, with no recent exceptional improvements. However, the industry segment is expected to retain their share in the near term future due to experimentation in other fields.

Hydrogen share in the energy market will continue to improve due to advances in fields like solar energy, and electrochemical manufacturing. One of the main disadvantages of solar energy production is always the need of transportation of excess generated energy. Latest approaches tend to use the energy carrying function of hydrogen molecule in order to store this excess energy and thus achieve higher selling prices, on demand. Electricity generated by solar plants is immediately used to generate hydrogen [from water or other source] and is stored for future use. The combination of the three factors leads to continuous increase in efficiency of solar plants and to the hydrogen storage market. Another recent use of hydrogen gas for energetic reasons has been established in different regions of the world [especially in UK]. Use of hydrogen gas [atomized] in diesel engines has been shown to provide significant fuel savings, partly due to increased energetic content of H atoms and partly due to great increases of distribution of diesel particles. The transformation of any diesel engine to a HHO – diesel engine is a mere modification that costs less than 600$ and takes up to two days of work.

Current estimation on overall hydrogen market show around 5% CAGR up to 2021. Advances in production, uses [energy carrying medium], transportation and environmental legislation requirements are the main factors supporting this estimation.