Novel composite membranes based on amino acids for wound treatment: Present and future

Wound treatment is a significant research field for the pharmaceutical industry. Biocompatible, non toxic, porous materials with high adhesion to skin cells are required in order to create the optimum wound dressing. Skin itself exhibits self healing ability. Wound dressings act in a two way fashion; they stop loss of important liquids from the body to the environment and they inhibit pathogens entry to the body via the wound. Optimum wound dressings are highly porous and based on bio compatible polymers such as chitosan. Fibrous nanomaterial coatings offer additional advantages such as more connection points to the skin surface, minimum permeability of pathogens, and an ordered microporous three dimensional modifiable network with tailored physical, chemical and biological properties. Hydrophilicity of the manufactured membrane coatings is a requirement that is easily met either by choosing a known hydrophilic polymeric matrix or by the tailoring of the coating surface’s structure.

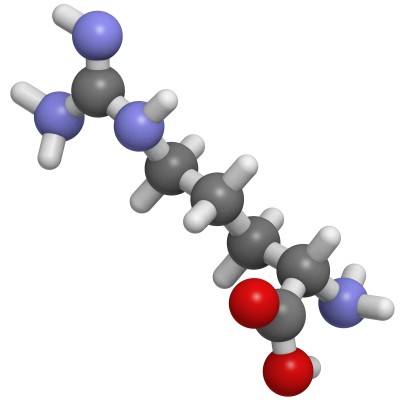

The combination of a polymeric matrix with a second compound leads to polymer blends and composites. The use of a polymer blend consisting of Chitosan modified with deacetylated arginine has led to the development of an excellent wound coating. Chitosan itself has been proven to improve intrusion of anti-inflammatory cells into the damaged area, via fibroblasts migration and proliferation and collagen deposition. In addition, it has been suggested that it exhibits haemostatic behavior through erythrocytes aggregation. Its antimicrobial activity can be significantly increased via the grafting of positively charged amino acids such as L-arginine and others. Positively charged L-arginine besides creating numerous positive local charges in the modified Chitosan polymeric chain, also increases the collage deposition rate as supported by research works.

Composite membranes’ attributes that affect the transportation inward and outwards the skin are selectivity and permeability which in turn depend on diffusivity and solubility of compounds in the matrix. Selectivity is a factor depending on structural and electrostatic properties of each molecule and the pore size distribution of each matrix. Permeability on the other hand depends mainly on pore size distribution and less on structural or electrostatic properties. Common issues reported with the use of a number of membranes is the accumulation of a species into a boundary layer that blocks the permeable pores and stops the entire exchange process. This phenomenon occurs due to low diffusivity of soluble species. Such issues are tangled by tailoring the pore size distributions of the 3D polymeric matrices.

The wound dressing coating based on the Chitosan/ Arginine polymer blend three dimensional fibrous structure offers great enhancement of wound healing, owing to a number of factors as discussed. Such works provide new guidelines for the design and manufacturing of wound coatings with tailored and increased properties based on combinations of properties of two or more compounds. Amino acids are a particularly important class of chemical compounds for this field due to their unique properties of easiness of insertion on polymeric backbones, biocompatibility, activity in biological processes and biodegradation. Immediate attention should be given to the construction of other amino acid based membranes as well as on the development of the presented amino acid blend with the addition of other functional amino acids. Composite formulations including more than one functional amino acid could lead to the manufacturing of revolutionary wound dressings.

The structural design of such coatings is also of greatest importance due to the permeability and selectivity characteristics that they exhibit. These properties are essential to the functionality of the membrane coating since they dictate which molecules can transport from the external environment to the damaged area, and which will be blocked. Knowledge of membrane manufacturing from other fields is extremely helpful for the design of the wound dressings. Fibrous microporous membranes are easily constructed by various techniques, with a continuously reduced cost.